|

||||

| PARTICULATE SUSPENSION Performance: SOLID Commercial vs. NANOPOROUS Synthetic Fe2O3 Powders | ||||

|

3/28/2024: Engineered Data LLC's Advanced Materials Group (www.Synthetic-Metals.com) made 3 unexpected discoveries during their

Whitepaper Radiation Shielding Hardening Research (in response to US Missile Defense Agency BAA #HQ0860-23-S-001.)

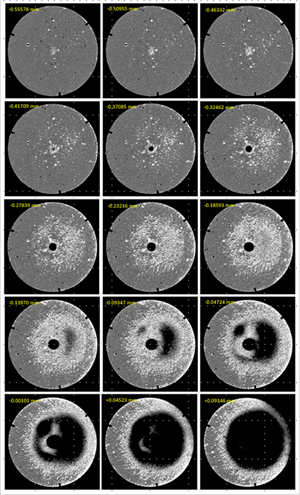

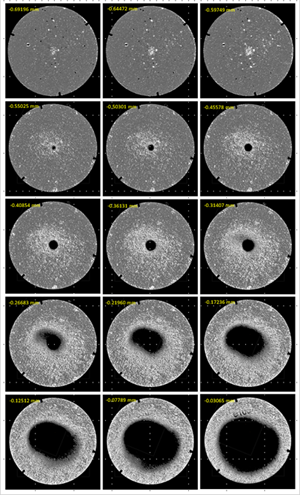

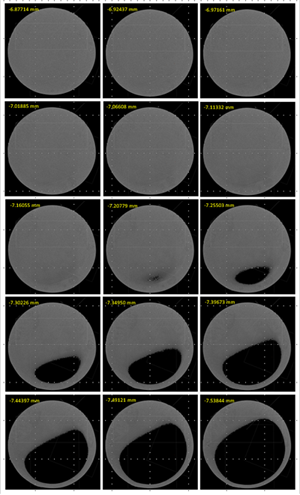

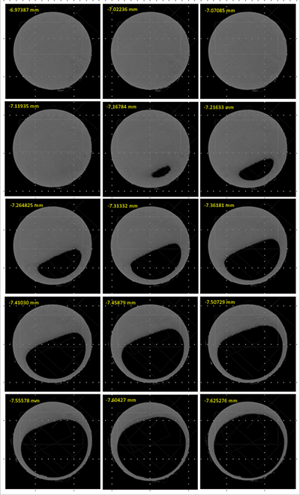

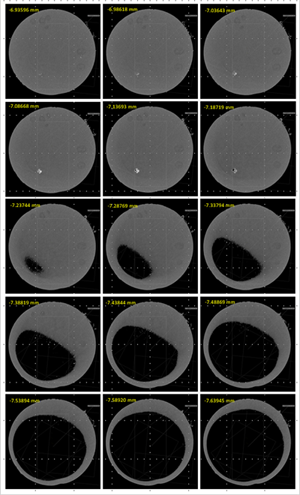

[a] SOLID micron and nano grain ferric oxide particles DISPLAYED SEDIMENTATION (located at the bottom of the sample cups) when suspended in silicone rubber: NANOPOROUS micron grain ferric oxide particles did not. [b] SOLID micron and nano grain ferric oxide particles DISPLAYED AGGREGATION (in the middle to bottom area of sample cups): NANOPOROUS micron ferric oxide particles did not, even when the crudest of mixing methods (manually stirring composite for 90 seconds) was used. [c] Oddly, surface area was not a factor that influenced particle dispersion. Three (3) Theories are advanced to explain these discoveries: [a] NANOPOROUS micron ferric oxide particles contain internal cavities that aggregately make each particle less dense than its Solid counterpart. Less dense particles are less susceptible to gravitationally induced sedimentation. [b] NANOPOROUS micron ferric oxide particles contain internal cavities that promote uniform particle dispersion when immersed in fluid composites. When particles come into contact with fluid, cavities not fully immersed in fluid remain buoyant by retaining their air pockets, that aggregately lift incompletely mixed particles to the surface, where they display as not completely mixed + present the opportunity to remixed until they appear no more. [c] NANOPOROUS micron ferric oxide particles contain rough, irregular external surfaces that, compared to solid particle's slippery surfaces, create increased particle surface shear that (like individual velcro threads) reduce particle mobility in fluid. |

|

|||

| SOLID Particle; COMMERCIAL | NANOPOROUS Particle; SYNTHETIC | |||

| MICRON-Sized GRAIN | NANO-Sized GRAIN | MICRON-Sized GRAIN | ||

| [3/24/2024] x-rayed composite consists of silicone rubber + ferric oxide powder, mixed in a 2.0 gram (s.r.) to 0.06 gram (f.o.) ratio, shaped like deformed (oversized top diameter) minature hockey pucks | ||||

|

|

||||

| Sample #1: "Amazon's Best" | Sample #2: SkyNanotechnologies.com | Sample #3: Synthetic-Metals.com | Sample #4: Synthetic-Metals.com | Sample #5: Synthetic-Metals.com |

| Grain Size: +/- 25,000nm | Surface Area: Not Listed | Grain Size: +/- 50nm | Surface Area: +/- 50m2/gram | Grain Size: +/- 7,700nm | Surface Area: +/- 106m2/gram | Grain Size: +/- 24,700nm | Surface Area: +/- 246m2/gram | Grain Size: +/- 24,700nm | Surface Area: +/- 255m2/gram |

| Particles VISIBLY AGGREGATING on BOTTOM | Particles VISIBLY AGGREGATING on BOTTOM | NO Visible Particle Aggregation on BOTTOM | NO Visible Particle Aggregation on BOTTOM | NO Visible Particle Aggregation on BOTTOM |

|

|

||||

|

ENLARGED IMAGE:

IMAGE #1

Partial VIDEO: From BOTTOM, moving UP Full Length VIDEO: From TOP, moving DOWN |

ENLARGED IMAGE:

IMAGE #2

Partial VIDEO: From BOTTOM, moving UP Full Length VIDEO: From TOP, moving DOWN |

ENLARGED IMAGE:

IMAGE #3

Partial VIDEO: From BOTTOM, moving UP Full Length VIDEO: From TOP, moving DOWN |

ENLARGED IMAGE:

IMAGE #4

Partial VIDEO: From BOTTOM, moving UP Full Length VIDEO: From TOP, moving DOWN Scanning Electron Microscope: IMAGE #4 |

ENLARGED IMAGE:

IMAGE #5

Partial VIDEO: From BOTTOM, moving UP Full Length VIDEO: From TOP, moving DOWN |

| USPTO Provisional Patent #63/573,678 | Filed 4/3/2024 @ 01:40:54 PM Z ET | 1st Named Inventor: Tim Rolf (DC) | 2nd Named Inventor: Howard Britton (MD) | 3rd Named Inventor: Ben Murphy, II (MI) | ||||

|

|

||||

|

|

||||

|

|

||||

|

|

||||